I decided to join the local homebrewers club Maltose Falcon to learn more about what other homebrewers are doing. This group was the first and remains the oldest homebrewers group in the USA.

A great benefit of this club is to participate with local comercial microbrewers in preparing a batch of beer. My first experience with this activity was with the LA Ale Works Brewery in Hawthorne, CA.

After the whirlpool “dry hop” additions to the wort, it was transfered to the fermenting after passing through a plate chiller. This is where I was graciously given a 5 gallon pull to take home to ferment on my own. This was approximately 2pm Saturday.

Personal obligations postponed my arrival home until about 4pm Sunday. Shortly after that, I transfered the 5 gallon bucket of wort to my sanitised 15 gallon Speidel fermenter. The guy at the brew supply shop advised me earlier in the day that there was no time for a starter and to pitch the yeast as soon as possible. To compensate for the lack of a starter, I used 2 viles of White Labs WLP001 instead of my usual one vile mixed with DME and spun for 2 days in a flask. It was only fitting, considering the name of this recipe: Double Up. This left me somewhat concerned, but I did pitch the 2 viles Sunday afternoon, without preparing a yeast starter.

Just as with my last batch, I dropped my Tilt into the fermenter and plugged in the Raspberry Pi so the fermentation gravity and temperature could be monitored from my phone.

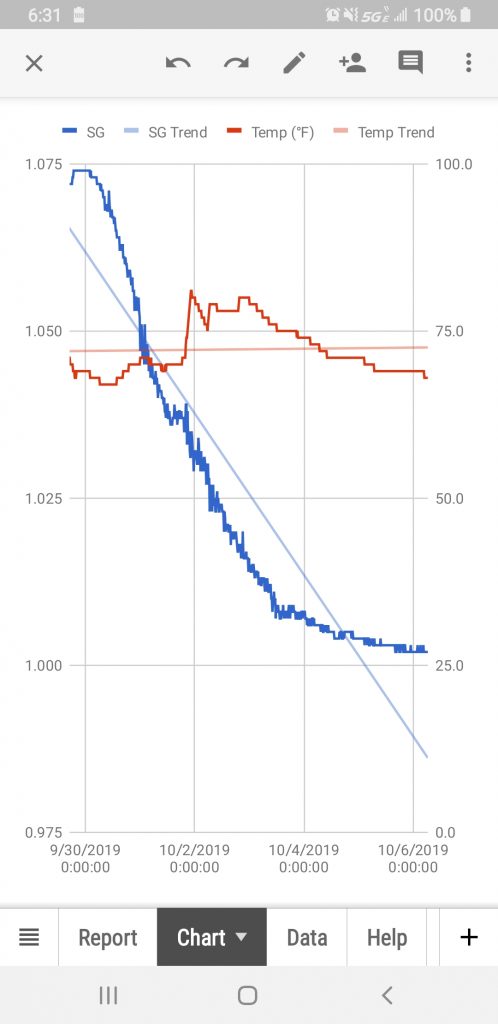

Original gravity read 1.074 at a temperature of 70 F. It was cooler than normal for this time of year, which made the fermenter temperature drop to 67 F after 20 hours has passed. This still seemed to be in the normal range. In addition, the gravity started it’s decent 10 hours after pitching yeast.

Fermentation proceeded as expected until about 45 hours had passed. At this point, the gravity appeared to be stuck at 1.038 with the temperature hovering around 70 F. Stuck for around 7 hours after steadily dropping up to that point.

Was it because I did not use a starter? Temperature too low, causing the yeast to drop out?

I decided to bring the temperature up and shake the fermentation vessel a bit. A small space heater was placed a few feet from the fermenter. It was in a small room. This brought the temperature up to 80 F before I turned the heater off for the night.

As illustrated in the graph, the temperature slowly retreated overnight after the heater was turned off. I ran the heater for about 45 minutes before heading off to work in the morning. But this time, the fermenter was wrapped in a fleese blanket. That kept the temperature stable while fermentation continued.

As you can see, there was a heater in the foreground to warm the room and a portable ac in the background for hot summer days.

The gravity bottomed out at 1.001. That makes this DIPA weigh in at 9.6% abv. Twelve sanitized pre-used 22 ounce bottles (all I had on hand) bottles were filled and capped October 12. The rest was kegged and CO2 pressurized. I usually give the bottles 4 weeks for carbonation and conditioning and two weeks for the keg.

The small 4 ounce sample I drew during the bottling had a full-body rich malty note. Very easy to drink.